Apple’s establishment of a cutting-edge lab in Shenzhen, China, underscores its commitment to extreme product testing, specifically designed to enhance the durability and performance of its flagship devices. By employing innovative testing techniques that simulate real-world conditions, the lab aims to address potential vulnerabilities that may arise during everyday use. Additionally, the collaboration with local experts not only refines these methodologies but also facilitates a deeper understanding of regional manufacturing challenges. As Apple navigates this intricate landscape, the implications for its future product offerings raise intriguing questions about quality, sustainability, and consumer expectations.

Overview of the New Lab

Apple’s new applied research lab in Shenzhen, China, represents a significant investment in product testing and quality assurance, with a focus on evaluating flagship devices under extreme conditions.

With an investment exceeding 1 billion yuan (approximately $138 million), the Shenzhen lab will rigorously assess the durability and performance of Apple products such as the iPhone, iPad, and Apple Vision Pro.

The lab’s strategic location facilitates close collaboration with local suppliers, allowing for efficient material testing and streamlined production processes.

By simulating diverse user experiences, the Shenzhen lab aims to uphold international quality benchmarks, ensuring Apple products meet the high standards expected by consumers.

This initiative underscores Apple’s commitment to innovation and excellence in product development and customer satisfaction.

Innovative Testing Methods

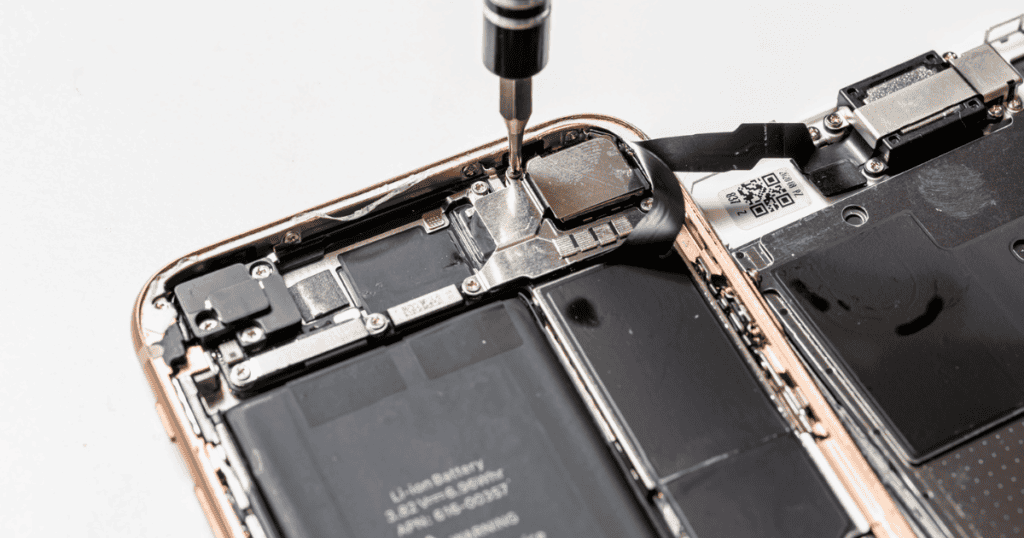

The Shenzhen lab’s commitment to rigorous product evaluation is reflected in its implementation of innovative testing methods designed to assess the durability and performance of flagship devices under extreme conditions.

By simulating real-world user experiences, the lab guarantees that products, such as the iPhone and iPad, can withstand high temperatures and intense physical activity. Advanced testing methods will rigorously evaluate the physical robustness of innovative materials, focusing on wear and tear to enhance product reliability.

Moreover, the lab will explore innovative reclamation approaches to integrate recycled materials into designs, balancing sustainability with performance.

This commitment to thorough durability testing is expected to lead to significant advancements in product design, preventing issues like previous concerns over device sturdiness.

Collaboration With Local Experts

Collaboration with local experts in Shenzhen is poised to enhance the effectiveness of product testing and development, leveraging regional expertise to drive innovation in durability assessments and material advancements.

By partnering with local tech firms and academic institutions, Apple aims to integrate specialized knowledge that fosters cutting-edge solutions in product testing. These collaborations will focus on refining durability testing methodologies and exploring new materials that can withstand extreme conditions.

Proximity to key suppliers also facilitates streamlined communication between research and production teams, allowing for immediate problem-solving and addressing manufacturing challenges efficiently.

Ultimately, this strategic collaboration with local experts is essential for Apple to enhance product reliability and elevate user satisfaction in its innovative offerings.

Impact on Product Durability

Rigorous testing conducted at the Shenzhen lab will greatly enhance the durability of products like the iPhone, iPad, and Vision Pro, ensuring they can endure extreme conditions and intense usage.

This strategic investment of over 1 billion yuan (approx. $138 million) indicates Apple’s commitment to high durability standards and reliability.

Key aspects of this initiative include:

- Extreme Temperature Testing: Evaluating performance under varying climatic conditions.

- Physical Activity Simulations: Examining how devices withstand rigorous daily use.

- User Experience Simulation: Replicating real-world challenges to identify vulnerabilities.

- Sustainability Alignment: Focusing on creating longer-lasting devices to minimize electronic waste.

Ultimately, this advanced testing in Shenzhen is set to greatly improve product durability, reinforcing user trust in Apple’s devices.

Addressing Manufacturing Challenges

Strategically positioned in Shenzhen, Apple’s new lab is poised to tackle manufacturing challenges by leveraging proximity to suppliers and advanced testing methodologies.

The facility focuses on evaluating new materials and production techniques to enhance product quality, ensuring that Apple products can withstand extreme temperatures and other demanding conditions.

By simulating user experiences under such stressors, the Shenzhen lab identifies potential issues early, allowing for timely interventions before products reach consumers.

This proactive approach fosters collaboration between research and production teams, streamlining communication and problem-solving processes.

Additionally, the significant investment of over 1 billion yuan demonstrates Apple’s commitment to overcoming manufacturing challenges and delivering exceptional quality in its products.

Future of Apple Products

How will Apple’s commitment to innovation and durability shape the future of its product offerings?

The establishment of the new lab in Shenzhen allows Apple to rigorously test its products under extreme conditions, ensuring high reliability and performance. This focus on durability will guide the development of next-generation Apple products, meeting consumer demand for sustainable technology.

Key projections include:

- iPhone SE 4, featuring an OLED display and enhanced camera capabilities.

- iPhone 17 lineup with a Slim model that elevates user experience.

- Upcoming software updates for iOS and macOS, enhancing device functionality.

- A dedication to reducing electronic waste through robust product development.

Apple’s future products will embody innovation, reliability, and sustainability as core principles.

Commitment to Quality and Innovation

Apple’s commitment to quality and innovation is exemplified by the establishment of its new Shenzhen lab, which focuses on thorough testing of products under extreme conditions to guarantee unmatched durability and performance.

This facility, with an investment exceeding 1 billion yuan, is dedicated to enhancing the reliability of flagship products like the iPhone, iPad, and Vision Pro. By simulating high temperatures and intense physical activities, the lab addresses potential manufacturing challenges, ensuring products meet international quality benchmarks.

Additionally, collaborations with local tech firms will drive advancements in testing methodologies and materials, reinforcing Apple’s dedication to innovation.

Ultimately, this initiative not only improves product durability but also enhances overall customer satisfaction, solidifying Apple’s reputation for excellence in the tech industry.

MacReview Verdict

In summary, Apple’s new lab in Shenzhen represents an essential step towards fortifying product durability and performance, akin to a blacksmith forging steel into resilient tools.

The innovative testing methods and collaboration with local experts not only enhance the quality of devices but also address potential manufacturing challenges.

This commitment to sustainability and excellence positions Apple to meet consumer expectations while advancing the future of technology, ensuring that flagship products remain robust in an ever-demanding market.